I have been modeling the Lehigh Valley railroad in HO for over thirty years. I grew up along the Susquehanna River, just across from the “Valley’s” Coxton yards. I was fortunate to ride on many yard switchers, pushers, and locals as a kid in the mid sixties. Sadly I never carried my Kodak often enough.

I began to obtain HO equipment in LV paint schemes from various manufacturers in the early 70s. Not always prototypically correct but attractive. I keep many of these on shelves today in my train room. In 1978 I began a push for better quality power and rolling stock. I met a hobby shop proprietor on Long Island who provided custom painting on the side. Atlas had just released their first GP-38’s and so several units later, including a variety of Athearn GP-9’s, F-7’s and SW’s; and I was on my way.

Working for the federal government means having to relocate periodically, and my L&S division has been housed in New York, Saudi Arabia, and now north Texas. The latest version of the railroad is located in an 11-½ X 11-½ irregularly shaped room, which was supposed to be a formal parlor. (No basements in this part of Texas) The trackplan is a simple point to point, but a junction permits continuous running. There were several pre-requisites, necessary to my interests. First, I wanted a fair sized steel mill with inter-plant trackage and large structures. An interchange with Bethlehem Steel’s PB&NE was a must. Second, a cement mill and an anthracite colliery (breaker) had to be large enough to provide adequate traffic. Wrapping these three unrelated industries into the space at hand would be tough enough, but the plan also had to be in a walk-around style. No head bangers for me, and access to the window was a must.

There was also an interest in reproducing large mountains to tunnel thru, at least one waterway to bridge, and an elevated section to provide some visual drama.

I like switchers, especially when M.U.-ed together back to back. So train length was limited operationally to about ten cars, and two switchers. I can operate longer trains on the main, but they stay there in continuous fashion primarily for guests.

In my world, the L&S begins at East Penn. The main arrives from behind a mountain-hugging curve, and passes the Beth Steel’s # 7 fabricating plant.

East Penn provides a passing siding to serve as junction for the PB&NE on the east end, and the Whitehall Cement Co. on the west. A large eight-foot long mountainside rising approx. 18 inches high serves as a 3D-textured backdrop, preventing a view of the rest of the room. Mainline trackage has a minimum radius of 22 inches, with branch line and industrial trackage curving to about 18 inches. Yes I know they are tight, but space and design consideration forced the compromise. Since most trains are short, and operate at fairly slow speeds, I have not encountered any serious difficulties.

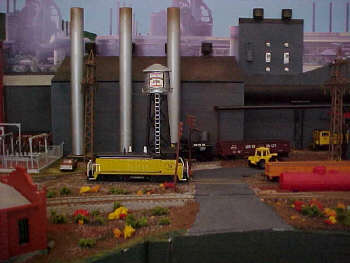

Bethlehem Steel is represented by several Walther’s kits, which are built as half or three quarter background relief structures. They blend in with commercial steel mill structure backdrop cutouts. (Can you find the room light switches, which are set in a corrugated siding panel to simulate a mill building?) Located on one leg of a “Y”, all track is stub-ended and enters or passes thru most of the buildings. I use conventional wiring and control, so one cab is dedicated to movements within the plant’s trackage.

|

|

The theory is that scrap metal is setout with occasional hopper traffic, and flats, coil car, gondola and boxcars are picked up with finished products.

Whitehall Cement is another Walther’s kit plus an older Life-Like building to add more bulk to the facility. Cement is stored here using covered hoppers while bagged cement is transported in boxcars.

|

|

The line curves west and ducks into a single portal tunnel. Walking around this peninsula style end of the bench work, one arrives at Hazle Creek Junction. The main exits the tunnel and continues on thru the junction and diamonds to parallel Hazle Creek. The main disappears from view around the bend of the mountainside. The branch line here crosses the main at grade, and over Hazle Creek on a plate girder bridge. The branch splits with the left leg entering a yard and industrial area. Four tracks here provide storage and activity for switching several businesses and a coal fired power plant.The right leg begins a 4% grade behind the industrial area, dead ends, and then switches back, crossing the valley, creek, and mainline on a steel viaduct.

|

|

The branch ends at the Glen Alden Colliery. Glen Alden is a two-track yard serving a large breaker and assorted supporting structures. The mine is almost totally surrounded by mine waste or culm material. It is one of the last surviving anthracite facilities in the country. Traffic here consists of loaded and empty hoppers via the switch back. Again, using cab control, a separate tethered throttle controls the Hazle Creek branch, industrial area and colliery yard.Right now, scenery is 75 % completed at East Penn and Beth Steel. There are always details, but I wanted to get this area to a somewhat finished state first, as it is visible on entering the house from the front foyer. I am now concentrating on the Hazle Creek area, and wiring the separate cabs.

I am something of a collector, and have to have at least one of everything being reproduced by one manufacturer or another. Although the era I prefer to model is the early 70’s, I have several name trains such as the Asa Packer and John Wilkes represented by IHC models on shelves around the room above the backdrop. More shelves are built into the bench work for car storage.

As I said, I like conventional wiring and cab control. I use both MRC and GML throttles and power supplies. Turnouts are hand thrown with Caboose Industry products. I purchased an MRC SoundMaster some years ago, and placed auto speakers in the facia. A tape deck is wired thru the SoundMaster for background railroad sounds.

Operations: there is no formal “staging” of trains. I like staging, but opted out of it for this railroad. Short turn around or STA’s operate from Hazle Creek to East Penn and back. Local switching will occur at Beth Steel and on the Hazle Creek’s branch lines. I like to just let a train run on the main while fiddling with something else.

Structures: I needed a coal breaker of some substantial size for Glen Alden. The Walthers New River mine was considered, but was to squatty or wide for the area. Also it lacked the height necessary and familiar to be an anthracite breaker.

I am now in the process of planning a structure based on the “boxy” Sullivan Trail Co. breaker, which existed in West Pittston until the early 90’s. I will use Evergreen corrugated sheet and window mullions for the basic framework. Many anthracite breakers were unique in that they had large doors to close over the loading tracks. The doors were protection against the winter elements considering the use of water in the cleaning process. A small powerhouse and other support buildings will complete the colliery.

A large power plant existed along the Susquehanna River in Exeter Township on the west bank. Coal traffic was brought in via the West Pittston and Exeter Ry, which was wholly owned by the Pennsylvania Power and Light Co. On my railroad, the plant is represented easily by a Walther’s kit with additional piping, and conveyor system from the coal dump.

I will also be looking for ideas on the curving steel viaduct, which will cross the valley. I figure it will run approximately four feet long and the height will vary from 4 to 8 inches.

Due to another job transfer, the layout will be torn down in early August 2001, and rebuilt in the Virginia suburbs of Washington, DC – with a walk-out basement, this time! I’ll keep you all advised.

– Chuck Huthmaker (Chuthmaker at AOL dot com)